SLA stands for Stereolithography, a type of resin-based 3D printing technology. It was one of the earliest 3D printing technologies developed in the 1980s.

Ideal for producing detailed prototypes, intricate jewelry, dental models, and other objects that demand high resolution. Commonly used in industries such as automotive, healthcare, and design prototyping.

Exceptional print resolution and surface finish. Suitable for producing intricate and delicate designs. Capable of printing objects with complex geometries.

Resins often contain chemicals that require careful handling, including proper ventilation and protective equipment.

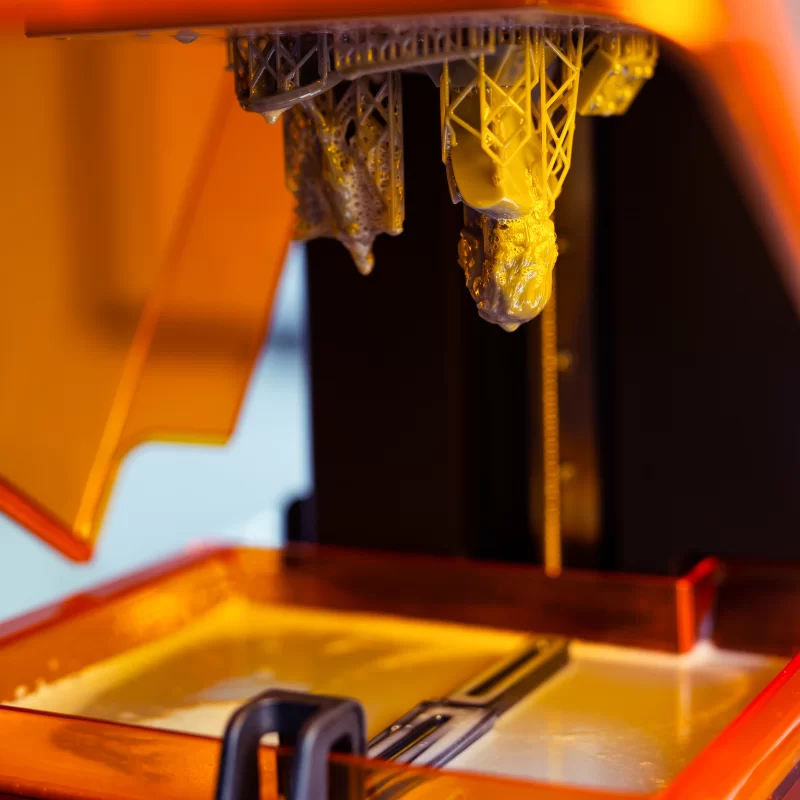

Uses a liquid resin that hardens when exposed to ultraviolet (UV) light. The 3D printer builds objects layer by layer by selectively curing the liquid resin using a UV laser or light source.

Resins come in various formulations, including standard, tough, flexible, and castable resins. Each type of resin caters to specific applications, providing a range of mechanical properties and finishes.

Offers high precision and intricate detailing, making it suitable for applications that require fine features and smooth surfaces.

Typically requires post-processing steps like washing and curing to remove excess resin and improve the final part's mechanical properties.

Limited in terms of build volume compared to other 3D printing technologies. Resin can be expensive, and not all resins are suitable for all applications.

SLA technology continues to evolve, with improvements in speed, material options, and the development of desktop-sized printers for wider accessibility.