Manual soldering is versatile, catering to a wide range of electronic devices and applications, from consumer electronics to industrial machinery.

The flexibility of manual soldering makes it an invaluable tool for repair and rework tasks, enabling the correction of errors and the enhancement of existing electronic systems.

Each solder joint is a testament to our commitment to quality. Rigorous inspection processes ensure that every connection meets stringent standards for durability and conductivity.

In the early stages of product development, manual soldering proves indispensable for prototyping and small batch production, allowing for quick iterations and adjustments.

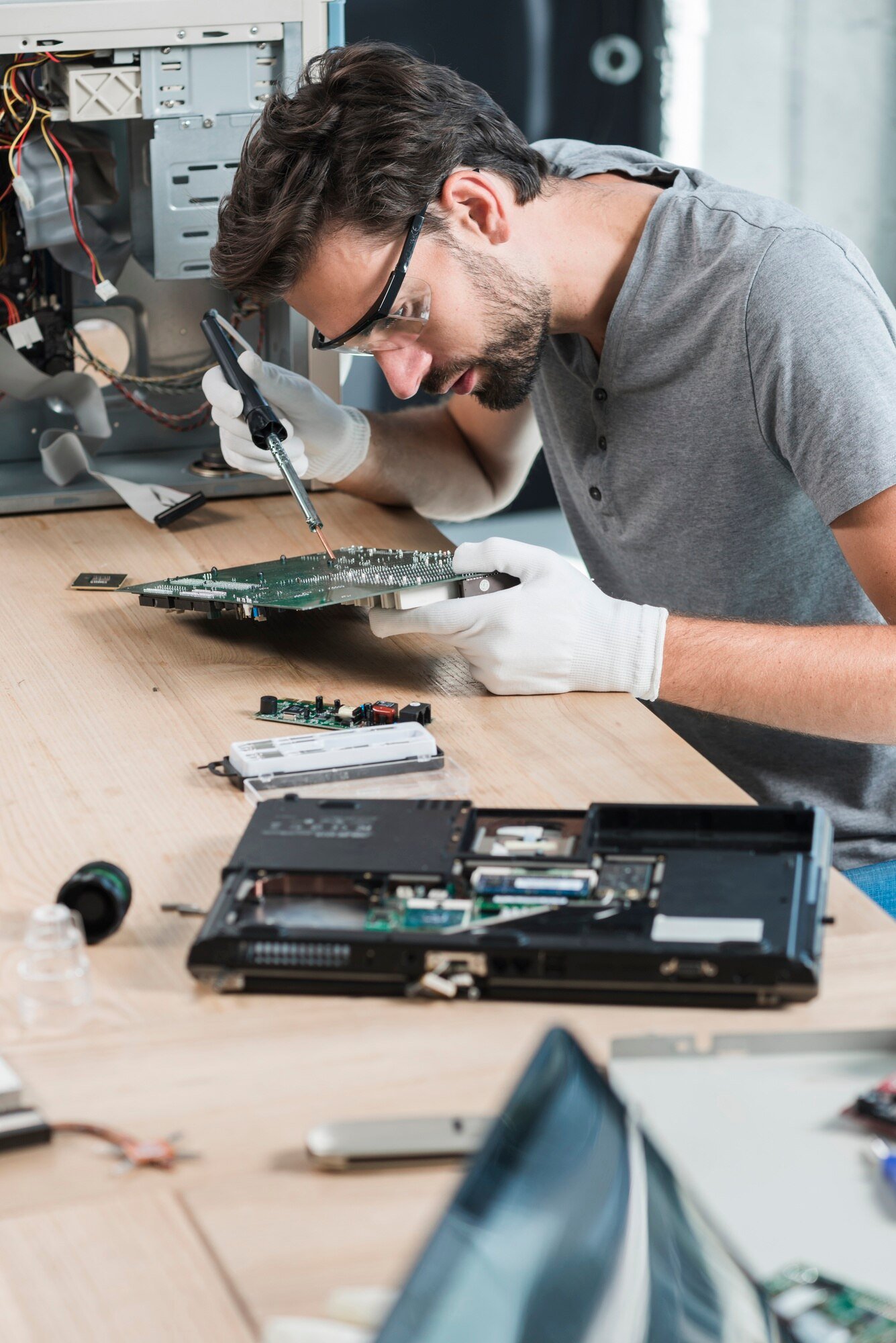

Manual soldering is an art that demands skilled hands. Our technicians are adept at delicately joining components to ensure optimal conductivity and reliability.

From intricate circuit boards to complex assemblies, manual soldering allows for customized solutions, accommodating the unique requirements of various electronic applications.

Precise temperature control is a hallmark of manual soldering, preventing overheating and damage to sensitive electronic components, ensuring longevity and performance.

While automation has its place, manual soldering adds a human touch to technology. Our skilled technicians bring experience and expertise to the soldering process, ensuring a level of precision and care that machines may lack.

Manual soldering excels in handling intricate and complex designs, navigating the nuances of diverse electronic layouts with finesse.

Our soldering technicians undergo continuous training to stay abreast of the latest techniques and technologies, ensuring that our manual soldering processes evolve with the ever-changing landscape of electronics.