Fused Deposition Modeling (FDM) is a widely used 3D printing technology. It falls under the category of additive manufacturing, where objects are created layer by layer from a digital model.

Supports are often necessary in FDM printing to prevent overhangs and ensure the accuracy of the final print. These supports are typically made from the same material as the object and are removed after printing.

Post-processing may be required to achieve a smoother finish. Techniques like sanding, painting, or coating can be employed to enhance the aesthetics of FDM-printed objects.

FDM printers are often associated with the do-it-yourself (DIY) and open-source communities. Many FDM printers are available as kits, allowing enthusiasts to assemble and customize their machines.

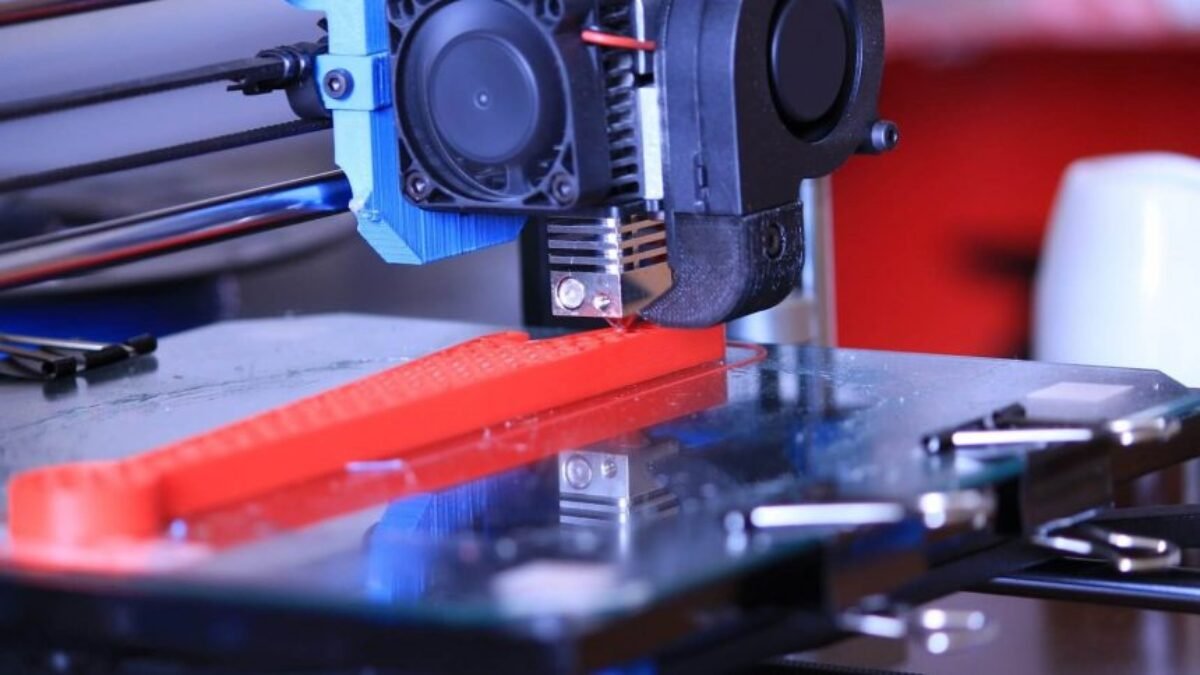

FDM primarily utilizes thermoplastic filaments such as PLA (Polylactic Acid), ABS (Acrylonitrile Butadiene Styrene), PETG (Polyethylene Terephthalate Glycol), and more. These materials are heated to their melting point and then extruded layer by layer to form the desired object.

FDM builds objects layer by layer, each layer bonding with the previous one as it cools. The layer thickness can be adjusted, impacting the print resolution and speed.

FDM is versatile, accommodating a range of design complexities and geometries. It is suitable for prototyping, manufacturing functional parts, and creating intricate models.

FDM printers come in various sizes, offering different build volumes to accommodate projects of different scales.

FDM is known for its cost-effectiveness, both in terms of printer cost and material expenses. The filaments used in FDM are generally more affordable compared to other 3D printing technologies.

FDM is used across various industries, including product design, engineering, education, and even in the production of custom consumer goods. Its ability to rapidly create prototypes makes it a valuable tool in the product development cycle.