Schematic to PCB Layout Design is a crucial phase in electronic product development, involving the transformation of a circuit schematic into a physical printed circuit board (PCB). This process is intricate and requires careful consideration to ensure the functionality, reliability, and manufacturability of the final product.

Define the arrangement of copper layers, ensuring proper grounding and power distribution. Balance the need for compactness with considerations for signal integrity.

Implement a robust ground plane and efficient power distribution to maintain stability and minimize noise. Consider separate power domains for sensitive components.

Perform DRC to identify and rectify potential design errors. Ensure compliance with manufacturing and assembly constraints.

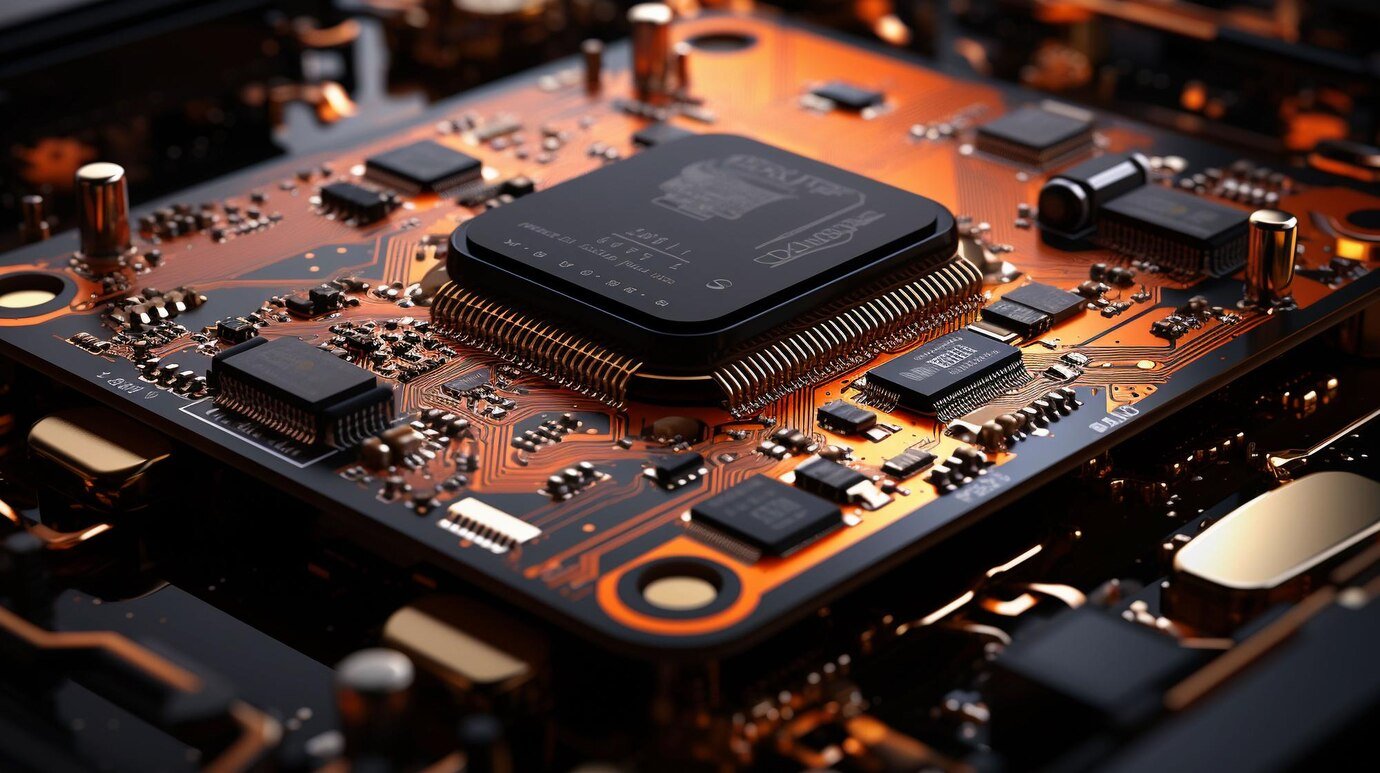

Integrate heat sinks, thermal vias, and other measures to manage and dissipate heat effectively. Prevent overheating that could compromise component performance and lifespan.

Translate circuit schematics into a digital format using specialized design software. Assign components, connectivity, and values to accurately represent the circuit.

Strategically position components on the PCB for optimal functionality and signal integrity. Consider factors such as heat dissipation, signal flow, and manufacturability during placement.

Establish electrical connections between components through copper traces. Optimize trace routing for signal integrity, avoiding interference and crosstalk.

Utilize 3D modeling tools to visualize the physical layout and identify any mechanical conflicts. Enhance collaboration between electronic and mechanical design teams.

Create prototypes to validate the design's functionality and performance. Conduct thorough testing to identify and address any issues.

Generate comprehensive documentation, including assembly drawings, bill of materials (BOM), and manufacturing files. Facilitate efficient collaboration with manufacturing partners.

Embrace an iterative design approach, making refinements based on testing and feedback. Strive for continuous improvement in both performance and manufacturability.